Summary. Drywall Pro-Cut champions the integration of fire strip on deflection heads, offering deflection head fire resistant solutions. These components boost safety by preventing fire spread, ensuring consistent quality and efficiency in modern construction practices.

When working in the ever-evolving construction industry, several regulations and precautions must be followed to ensure the safety of all workers. At Drywall Pro-Cut, we pride ourselves on manufacturing components that optimise a worksite for these health and safety purposes. Using fire strip on deflection heads, we can offer the ability for movement within drywall partitions that are resistant to burning.

As specialists in offsite solutions that exude high performance and efficient working, we understand the demands of construction today. For instance, our fire-rated deflection head details are manufactured and cut by us. In addition, we provide our services to businesses nationwide. Continue reading to find out everything you need to know.

Before we move on to the specifications of fire strip on deflection heads, it’s vital to understand the initial component itself.

What is a deflection head?

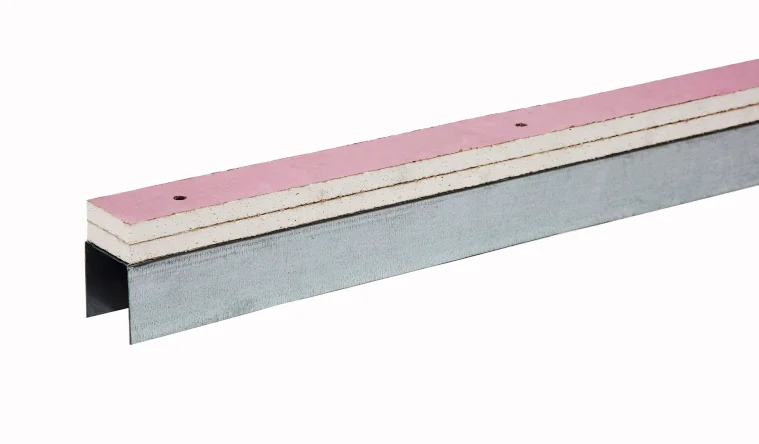

A deflection head is essentially a component within the structure of the head of a drywall partition, that allows for movement. When is a deflection head required? Deflection (the movement) is almost always a consequence of live and dead loads in the roof or on the floor. At Drywall Pro Cut, we offer high quality deflection heads made offsite.

What is a fire strip?

By incorporating the fire strip onto deflection heads, you immediately stop the spread of fire between heads through an intumescent gap sealant. They’re easy to install and give the lead of construction peace of mind that all aspects of partitions are safe when in close proximity to machinery and tools. Fire strip for doors is also a common use for such a component.

Why have them pre cut by us?

Our ‘Made & Delivered To You’ service lets us manufacture and send you deflection heads with fire seal. But why would pre cut applications benefit your business?

Inconsistency in Applications

While cutting drywall applications onsite is a common occurrence, this can cause detrimental effects on a construction company’s results, time and budget. In most cases, construction requires a large team of site workers, which often consequents in components being inconsistent. Exact specifications within the drywall and its additional parts are imperative to ensure stability. This becomes problematic if the number one priority of uniformity in construction work and dimensions varies.

By utilising offsite Drywall suppliers in the UK, you have a guarantee of invariable results. Pioneers in drywall and compatible components, we can batch-produce applications through our bespoke service. We can produce fire-resistant deflection heads to meet your size and shape requirements no matter the specifications required. All you need to do is discuss this with one of our specialists.

Waste of Time & Money

Additionally to the lack of precision and consistency, the manufacturing of such parts requires large amounts of labour and time. This would increase waste, which can become costly for your company. By utilising our offsite services, you are simply minimising these costs. We take care of all of our waste in the most efficient way possible. Also, we can adhere to large batch quantities in an agile fashion. This is through experience and the use of state-of-the-art equipment.

Get in Touch Today

Are you looking for fire strip on deflection head manufacturing in the UK? Get in touch with one of our team members today for further information on how we can enhance your construction site’s fire safety.

Furthermore, if you found this blog useful, why not take a look at a previous one: Builders Work Openings: Everything You Need To Know