At Drywall Pro-Cut, we specialise in providing innovative solutions to streamline complex construction projects. Our recent involvement in implementing prefabricated partitions above bathroom pods for a new hotel project highlights our commitment to delivering efficient and quality-driven solutions. This blog explores the advantages and the process of integrating prefabricated partitions in commercial construction, particularly in hospitality developments.

The Role of Prefabricated Partitions in Modern Construction

Quality and Efficiency

Prefabricated partitions offer unparalleled precision and quality, made possible by offsite manufacturing processes. For the hotel project, choosing prefabrication allowed us to maintain high standards of quality control outside the traditional onsite construction constraints, ensuring each partition perfectly met the project’s specifications.

Customisation for Specific Needs

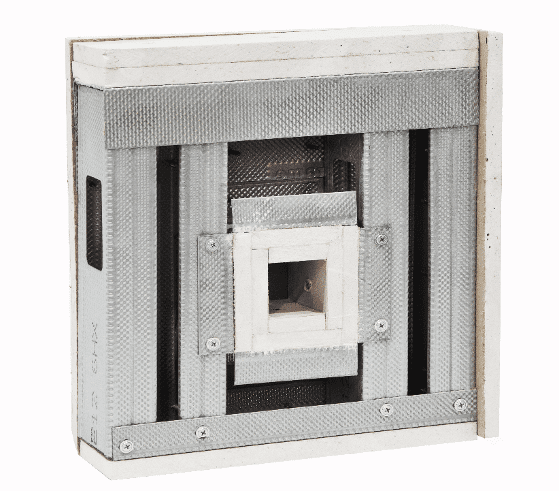

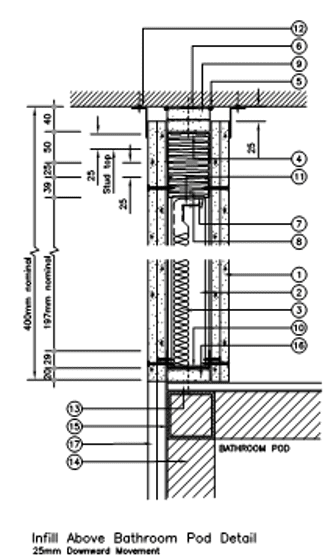

Each construction project carries its unique challenges, such as space constraints or specific safety requirements. For the hotel, we customised fire-rated partitions to accommodate essential ductwork, which was not possible with standard shaft wall solutions due to access restrictions. This adaptability is a testament to the flexibility of prefabricated solutions.

Detailed Insights into the Prefabrication Process

Design and Collaboration

The process began with meticulous planning and collaboration with the manufacturer’s technical team to produce detailed construction drawings, ensuring all project requirements were met precisely.

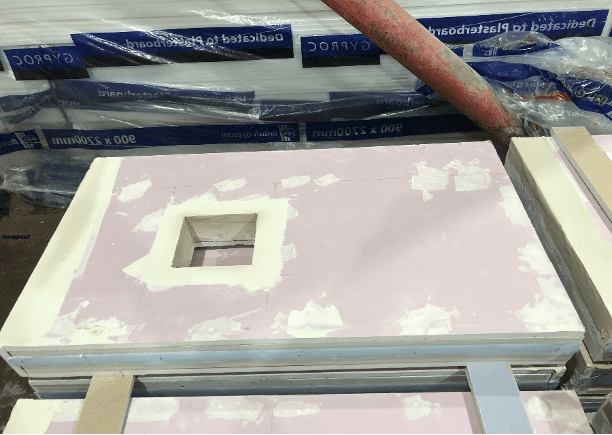

Offsite Manufacturing

The partitions were assembled offsite, with frameworks and one side boarded, including a tape and joint finish. This preparation significantly reduced the complexity and duration of onsite work.

Onsite Integration

Once delivered, the installation involved simply positioning the prefabricated units, securing them in place, and attaching pre-cut boards to finalise the structure. This method not only streamlined the entire construction process but also minimised the disruption and debris associated with traditional building methods.

The Advantages of Using Prefabricated Partitions

- Efficiency: Significantly cuts down on-site construction time, enabling faster project completion.

- Quality Control: Manufactured in a controlled factory setting, ensuring high-quality outcomes.

- Customization: Tailored to meet the exact requirements of the project, including aesthetic and functional needs.

- Reduced Waste: Less waste produced on-site due to precise manufacturing and reduced material usage.

The Future of Construction: Embracing Prefabrication

The success of prefabricated partitions in the hotel project is a clear indicator of how the construction industry is evolving towards more sustainable and efficient practices. Drywall Pro-Cut continues to pioneer this shift, constantly seeking new ways to enhance construction methodologies through prefabrication.

Conclusion

As the construction industry moves forward, the integration of prefabricated elements like partitions is set to play a pivotal role in shaping the future of building.

With Drywall Pro-Cut, experience the next level of construction efficiency and quality on your projects.