Smarter, Faster, Safer Construction

In 2025, speed, precision, and compliance define the future of interior construction. At Drywall Pro-Cut, we’re helping contractors, developers, and architects deliver projects faster and cleaner through offsite manufactured deflection heads – engineered for efficiency, quality, and sustainability.

Whether you’re managing a commercial build, education campus, or residential development, switching to pre-cut deflection heads saves time, reduces risk, and ensures every component arrives ready to install.

What Is a Deflection Head?

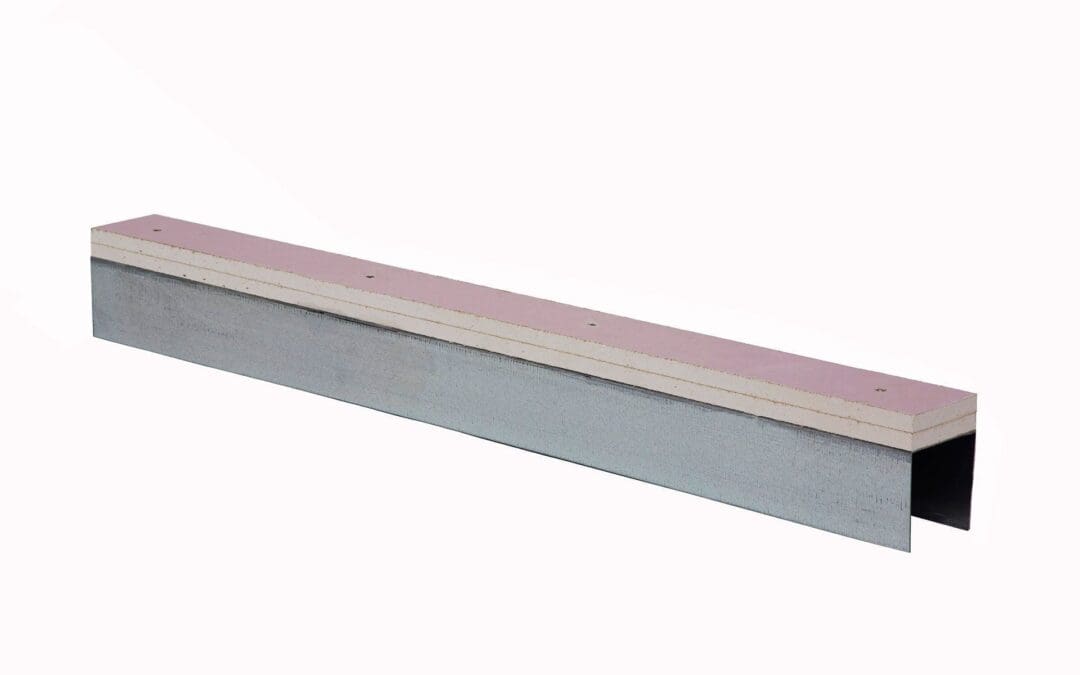

A deflection head allows vertical movement between structural slabs and drywall partitions – maintaining integrity even when a building flexes or settles. They’re essential in high-rise and large-scale buildings where vibration, temperature, and load changes cause movement between floors.

At Drywall Pro-Cut, every deflection head is cut to precise height and depth, complete with fire-rated board linings when required. This ensures compliance with British Gypsum or Siniat specifications, delivering fire, acoustic, and structural performance without the need for on-site cutting.

Why Offsite Manufacture Is the Future

1. Precision You Can Trust

Using CNC technology and controlled factory conditions, we produce deflection heads that fit exactly first time – ensuring tighter tolerances, cleaner finishes, and reduced snagging.

2. Proven Time and Cost Savings

Offsite production saves up to 40% of installation time. Installers spend less time cutting, measuring, and cleaning, while project managers gain more programme certainty. Labour productivity improves, and costs fall – a critical advantage on multi-phase and high-rise schemes.

3. Measurable Sustainability Benefits

By manufacturing offsite, we prevent hundreds of kilograms of plasterboard waste per project.

This supports BREEAM Wst 01 credits, reduces skip usage, and contributes to contractors’ net-zero carbon targets.

4. Full Building Safety Compliance

All deflection heads are manufactured under ISO 9001-certified processes with CCPI traceability, ensuring Golden Thread compliance under the Building Safety Act 2022. Each delivery includes clear documentation for audit-ready transparency.

Technical and Design Flexibility

- Compatible with Glasroc, Duraline, or Siniat systems.

- Manufactured to any size, depth, or gauge.

- Optional fire and acoustic linings.

- Delivered labelled and batched by floor or zone.

- Ready to install, saving days of on-site fabrication.

Where Pre-Cut Deflection Heads Add Value

| Sector | Benefits |

|---|---|

| Commercial & Office Fit-Outs | Faster installation, cleaner sites, reduced disruption |

| Education & Healthcare | Enhanced compliance and controlled site conditions |

| High-Rise Residential | Sequenced batching reduces logistical complexity |

| Refurbishment Projects | Eliminates cutting in occupied or sensitive environments |

Why Contractors Choose Drywall Pro-Cut

- Unmatched Programme Certainty: Sequenced, labelled, and delivered ready to install.

- Guaranteed Compliance: Built to British Gypsum and Siniat specifications.

- Nationwide Capability: Delivering to sites across the UK, from London to Glasgow.

- End-to-End Partnership: We collaborate from specification to completion.

- Sustainability at Scale: Supporting carbon reduction and circular economy goals.

FAQs

1. How much time can offsite deflection heads save on a project?

Most projects see up to 30-40% time savings, equating to several weeks on large commercial or multi-storey developments.

2. Are deflection heads fire-rated and compliant with UK building standards?

Yes. All our systems use British Gypsum and Siniat fire-rated boards, fully tested to EN 1364 and BS 476 standards for fire and acoustic performance.

3. Can I order custom deflection head sizes?

Absolutely. We manufacture to your exact project specifications, including height, gauge, and optional fire strip installation.

4. How do offsite deflection heads improve site safety?

By eliminating cutting, dust, and manual handling, sites become cleaner, quieter, and safer, supporting H&S compliance and workforce wellbeing.

5. How can I get a quotation for pre-cut deflection heads?

Send your drawings or take-offs to enquiries@drywallpro-cut.co.uk. Our technical team will provide a detailed quote and specification review within 48 hours.

Building the Future of Drywall Efficiency

With tighter deadlines, stricter regulations, and sustainability targets, offsite drywall manufacturing is no longer optional – it’s essential.

At Drywall Pro-Cut, we’re helping contractors meet these challenges with precision-engineered deflection heads that deliver faster, safer, and more sustainable construction.

Email: enquiries@drywallpro-cut.co.uk

Phone: 01827 213201

Visit Drywall Manufacturing